Beyti Compressed Air Leak

Tasnee Compressed Air Demo Report

September 24, 2018

Air Liquide Electrical Inspection

September 24, 2018Beyti Compressed Air Leak

Leak Detection:

Find leaks quickly and easily with Ultrasound technology

Ultrasound leak detection covers a wide range of leaks: pressure or vacuum and any type of gas.

Sound dependent: ultrasound instruments detect the turbulent flow produced as the gas moves from the high-pressure side to the low-pressure side of a leak. Using the characteristics of Ultrasound, locating leaks is fast and easy to do so because of:

- Directionality of sound waves makes locating the source easy.

- Intensity of signal: the closer you get, the more sound you detect.

- Fixed frequency, making it effective to locate even in a loud factory environment!

In many facilities Ultrasound detection instruments are used for safety, environmental, energy or quality assurance programs: - Compressed air costs money! Avoid energy loss by fixing your leaks

- Industry average 31% of energy use can be avoided by just fixing leaks!

- Reduce running hours / wear and tear on existing equipment

- In many cases a lower spec or shut down of a compressor can be the result

- Specialty gasses

- Cost avoidance, expensive to buy or produce o Environmental impact of certain gasses

- Production efficiency

- Achieve better efficiency of the process

- Run pressures or vacuum pressures at desired levels

- Inspection efficiency & inspector safety

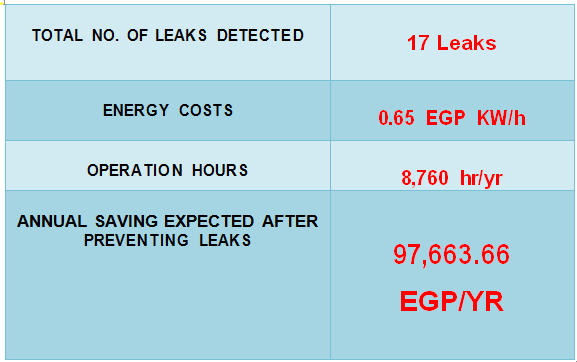

AIR LEAKS REPORT:

Copyright 2008 by UE Systems Inc. Patent Pending.

AIR LEAK ASSESSMENT SUMMARY:

AIR LEAKS LOCATIONS: