Detecting electrical problems using Vibration Analysis

Detecting bearing damage using Shock plus method 1

September 3, 2018

Increasing ROI in the Mining Industry

September 3, 2018Detecting electrical problems using Vibration Analysis

The Problem

It seems for the first while as it is an outer race damage at the bearing, but the motor noise was not like it used to be heard.

We repeat measurements at the same point and the measurements changed, also we noticed that the RPM of the motor may not be constant and it was obvious for me at the vibration spectrum.

Also there was a modulation, and the modulation was appearing at one reading and disappear and the next, As there was a peak at 37.5 Hz which is not related to any of machine components.

The solution

After a huge number of measurements and analysis for 3 days, we requested to check the drive and we found the reason of the unstable measurements and the fault was from the Drive of the motor, it was require fine tuning as the motor was DC motor the input Voltage for the motor was not stable / constant it was varying from 80 volts to 210 volt,

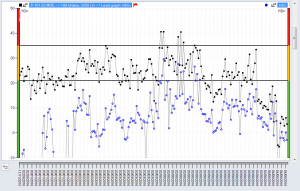

As per our recommendation to tune the drive, The following trend shows the variation of readings during the three days and after tuning the drive.

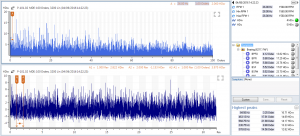

The following picture shows the vibration spectrum and time signal after Drive Tuning

And the following SPM Measurements for the same bearing after Drive tuning without and bearing change or mechanical maintenance