Leak Detection Energy Saving Demo

Aramco Valve Inspection

September 24, 2018

Ma’aden Phosphate Valve Inspection Report

September 24, 2018Leak Detection Energy Saving Demo

Leak Detection:

Find leaks quickly and easily with Ultrasound technology

Ultrasound leak detection covers a wide range of leaks: pressure or vacuum and any type of gas.

Sound dependent: ultrasound instruments detect the turbulent flow produced as the gas moves from the high-pressure side to the low-pressure side of a leak. Using the characteristics of Ultrasound, locating leaks is fast and easy to do so because of:

- Directionality of sound waves makes locating the source easy.

- Intensity of signal: the closer you get, the more sound you detect

- Fixed frequency, making it effective to locate even in a loud factory environment!

In many facilities Ultrasound detection instruments are used for safety, environmental, energy or quality assurance programs: - Compressed air costs money! Avoid energy loss by fixing your leaks

- Industry average 31% of energy use can be avoided by just fixing leaks!

- Reduce running hours / wear and tear on existing equipment

- In many cases a lower spec or shut down of a compressor can be the result

- Specialty gasses

- Cost avoidance, expensive to buy or produce o Environmental impact of certain gasses

- Production efficiency

- Achieve better efficiency of the process

- Run pressures or vacuum pressures at desired levels

- Inspection efficiency & inspector safety

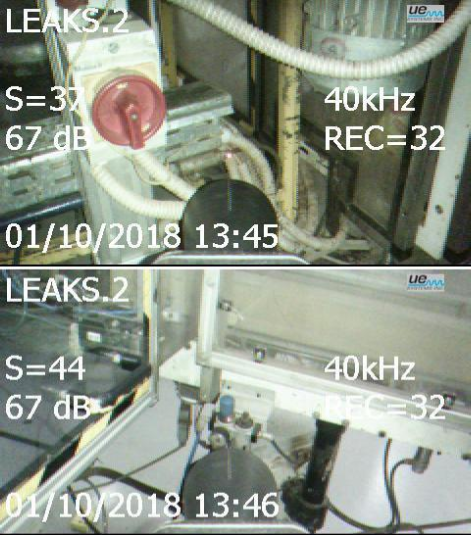

AIR LEAKS REPORT:

Copyright 2008 by UE Systems Inc. Patent Pending.

Copyright 2008 by UE Systems Inc. Patent Pending.

- The values presented in the tables are not stated as factual LPM measurements.

- These tables are provided solely for convenience and should only be used as a general guideline.

- Factors such as turbulence, leak orifice configuration, pressure, moisture and instrument sensitivity can affect your results

AIR LEAK ASSESSMENT SUMMARY:

AIR LEAKS LOCATIONS:

SUMMARY:

- Compressed air is one of the most costly utilities in a facility today. A simple program of

leak. - inspection and repair can go a long way towards reducing excessive energy costs.

When conducting a compressed air or steam trap survey, you should always calculate

your savings. Energy savings mean big dollar savings as well as a significant increase in

production, asset availability and product value. Energy savings, or “cost avoidance” is

not only important to your company’s bottom line, it will help. - A major advantage to ultrasound leak inspection is that as a high frequency, short wave

signal, ultrasound emissions tend to be localized around the leak site. By scanning an area

with an ultrasound instrument, a user will follow the sound of the leak to the loudest point.

Once identified, the leak amplitude can be noted and used in UE Systems’ compressed gas

reporting tool for reporting, cost analysis and environmental impact.