KOC Valve Inspection Report

Ma’aden Phosphate Valve Inspection Report

September 24, 2018

Tasnee Value Inspection Report

September 24, 2018KOC Valve Inspection Report

VALVE INSPECTION:

How Ultrasonic Valve Leak Detection Works

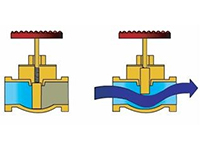

As fluid moves from the high pressure side of a valve through the

seat to the low pressure side, it produces turbulence. This

turbulence generates ultrasound which is detected by the

Ultraprobe and translated, via heterodyning, down into the audible

range. The translated ultrasounds are heard through headphones

and seen as intensity increments, usually decibels on a display panel.

Leak Detection Method

Inspection methods vary depending on the type of valve. Therefore the primary rule is to know the details of your system, including the way a specific valve may work under specific conditions. For example, is the valve normally open or normally closed? In order to determine valve condition such as leakage or blockage: touch two test points upstream of the valve (points A and B). On the first test point (test point “A”) reduce the sensitivity (received amplitude) of the instrument until the intensity indicator on the display panel reads about 50% of scale. If the instrument has frequency tuning, you may also use this feature to hear the valve sound quality more clearly by changing the frequency. Simply tune the frequency (usually 25 kHz) until the sound you would expect to hear becomes clear. It’s that simple.

Next, touch two test points downstream of the valve (points C and D) and compare intensity levels. If the sound is louder when comparing the first downstream (C) with the second upstream test point (B), the fluid might well be is passing through. If the compared downstream sound level is low, the valve is closed. If the second downstream test point (D) is louder than the first downstream test point (C), this indicates the sound is transferred from a source further downstream and indicates the valve may not be leaking. Ultrasonic valve inspection is considered a “positive” test in that an operator can instantly identify sound quality and intensity differentials and thereby determine operating condition accurately.

Sound analysis can also be used to indicate the amplitude and movement of fluid between the upstream and downstream test points.

VALVE INSPECTION METHODS:

Inspecting valves for leakage, four points of measurement taken for comparison:

Example 1: If points (A), (B), (C), (D), and (E) are close to being equal, then the

valve is not leaking. Ultrasound is created by a gas or fluid passing through a

restriction. If the readings are equal, then there is no turbulence generated at point

(C).

Example 2: If readings (A) and (B) are equal, but reading (C) is higher and the

readings (D) and (E) are lower, then the valve is leaking or failed. We can make

this conclusion because reading (C) is higher.

Example 3: If reading (A) and (B) are equal and reading (C) is higher, but

reading (D) is higher than (C) and reading (E&F) are even higher, then the

ultrasound is being generated from a source downstream of reading (E&F).

Because the readings are increasing, ultrasound is very directional.

KOC VALVE INSPECTION REPORT:

Point A

Point B

Point C

Point D

The reading above taken from the inspected valve was the same as Example (2):

If readings (A) and (B) are equal, but reading (C) is highest and the readings (D) is lower, then the valve is leaking. We can make this conclusion because reading (C) is higher.

CONCLUSION:

To determine whether a valve is leaking in closed condition, simply listen

to the valve and determine if there is turbulent flow. For leak detection

use the ABCD method to confirm your diagnoses NOW YOU CAN

inspect your valves accurately and fast using the UE SYSTEMS

Ultraprobes.