Lubrication Training Modules

PrimeGear Academy provides trainings for three main lines in the field of lubrication:

- Maintenance team (engineers and technicians).

- Reliability and Inspection Maintenance Team (Engineers & Technicians).

- Laboratory technicians (mainly chemists).

Register for this Training

Powered by

Industrial Lubrication Fundamentals ( ILF )

| Training overview | ||||||||||||||||||||

| An introduction to optimal lubrication practices, which covers the common activities of a lubrication. A must know knowledge for maintenance team in each and every industry. This course is tailored for beginners who know nothing about lubrication, great for skilled technicians and junior engineers. | ||||||||||||||||||||

| Training Main Topics | ||||||||||||||||||||

|

|

|||||||||||||||||||

Machinery Lubrication Analysis – Level I (MLA I)

| Training overview | |||||||||||||||||||

| An introduction to optimal lubrication practices, which covers the common activities of a lubrication. A must know knowledge for maintenance team in each and every industry. This course is tailored for beginners who know nothing about lubrication, great for skilled technicians and junior engineers. | |||||||||||||||||||

| Training Main Topics | |||||||||||||||||||

|

|

||||||||||||||||||

Machinery Lubrication Analysis – Level II (MLA II)

| Training overview | |||||||||||||||||||

| Maintenance professionals in Oil Analysis II will gain the knowledge they need to properly sample, monitor and detect additive, thermal and particle factors that degrade lubricants via on-site tests and lab analysis. | |||||||||||||||||||

| Training Main Topics | |||||||||||||||||||

|

|

||||||||||||||||||

Mobile Equipment Lubrication

| Training overview Mobile Equipment Lubrication | |||||||||||||||||||||

| Mobile Equipment Lubrication Training provides the foundational skill set for applying best lubrication practices and product knowledge in the related field. This course is tailored to cover all the knowledge in the field of internal combustion engines from basic level to advanced one | |||||||||||||||||||||

| Training Main Topics | |||||||||||||||||||||

|

|

||||||||||||||||||||

Food Processing Equipment Lubrication

| Training overview | |||||||||||||||||||

|

When it comes to food processing, effective lubrication is fundamental to reliable and efficient manufacturing. When the Food Safety Modernization Act (FSMA) was enacted in 2011, manufacturers contributing to the creation of food, pharmaceuticals and dietary supplements were mandated to implement systems and controls that specifically address the hazards which impact the safety of the food supply. This course focuses on understanding the FSMA, how it impacts your lubrication program and the lubricants used |

|||||||||||||||||||

| Training Main Topics | |||||||||||||||||||

|

|

||||||||||||||||||

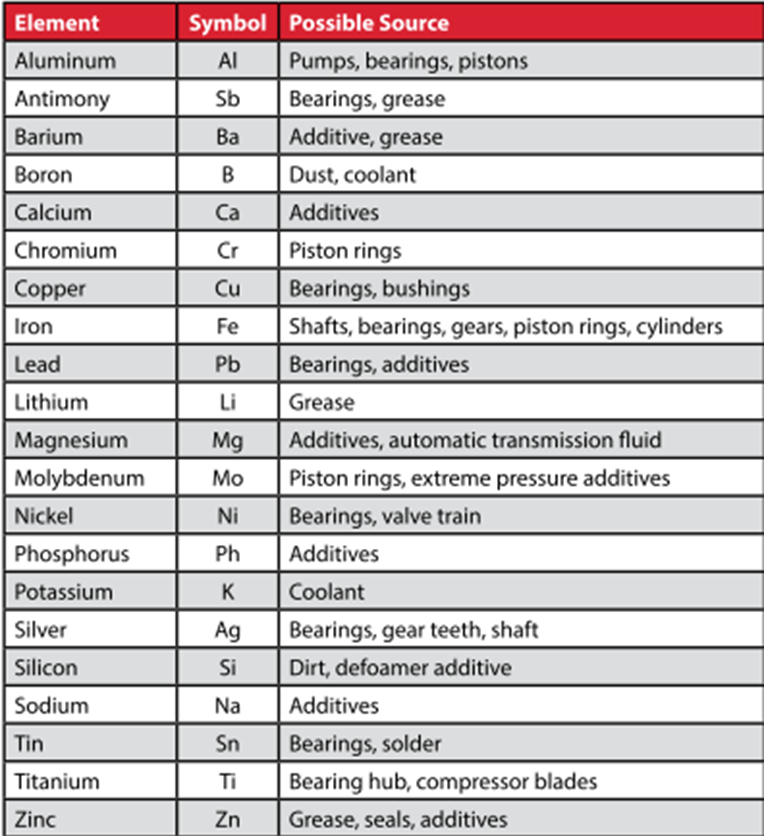

Oil Analysis Report Interpretation

| Training overview | ||||||||||||||||||||||||

| In this course, you will learn a systematic approach to translating oil analysis reports into actionable maintenance decisions. You will learn how to select the right tests for measuring the right data points for specific processes, environments and machine conditions. The course also touches on achieving accurate and consistent data collection, removing data noise to accurately identify false results, elemental analysis interpretation, interpreting metallurgical composition combinations to identify wear modes, setting key performance indicators (KPIs) and alarm limits. | ||||||||||||||||||||||||

| Training Main Topics | ||||||||||||||||||||||||

|

|

|||||||||||||||||||||||